Exploring the Different Types of Turning Inserts and Their Applications

Home › Product News › Exploring the Different Types of Turning Inserts and Their Applications

Home › Product News › Exploring the Different Types of Turning Inserts and Their Applications

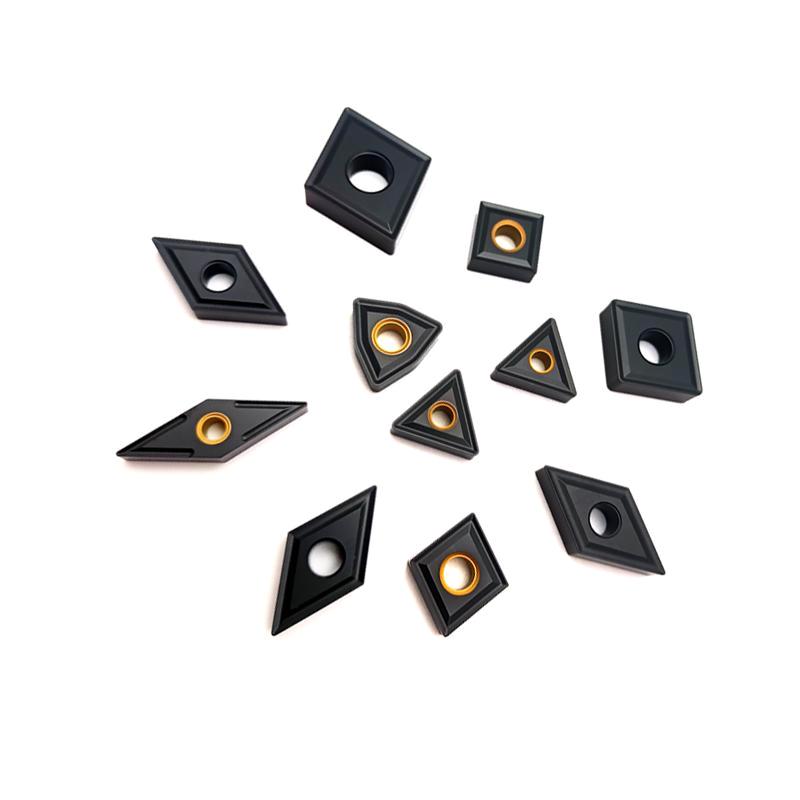

Turning inserts are an essential tool for any machinist or engineer. They are used in a wide variety of applications, from cutting and shaping metal to finishing and polishing. With such a wide variety of sizes, shapes, and materials available, it can be difficult to decide which type of turning insert is best for the job. In this article, we will explore the different types of turning inserts and their applications.

The first type of turning insert is a flat insert. These are most commonly used for general turning operations. Flat inserts are ideal for creating a flat finish on the work piece and can be used for light to medium-duty operations. They are available in a variety of materials, such as carbide, cermet, and coated grades.

The second type of turning insert is a round insert. These are used for operations such as drilling, reaming, and facing. Round inserts are designed to provide a smooth, precise finish on the work piece. They are available in a variety of materials, including carbide, cermet, and coated grades.

The third type of turning insert is an indexable insert. These are used for operations such as grooving, parting, and threading. Indexable inserts are designed to provide a precise finish with minimal effort. They are available in a variety of materials, including carbide, cermet, and coated grades.

Finally, the fourth type of turning insert is a tool holder insert. These are used for operations such as milling and grinding. Tool holder inserts are designed to provide a secure fixture for the tool and are available in a variety of materials, including carbide, cermet, and coated grades.

In conclusion, there are a variety of turning inserts available for a variety of applications. Each type of insert has its own advantages and disadvantages, so it is important to select the right insert for the job. By understanding the different types of turning inserts and their applications, you can ensure that you have the best tool for the job.

Write a Comment