When the lathe is being machined, chatter lines appear on the parts. This situation can be described as basically everywhere in the factory with CNC machine for metal.

You may often encounter it when you are finishing machining. It does not have a beautiful appearance. It needs to be quietly polished with fine sandpaper or oilstone. In particular, electroplating is required after high precision requirements. At this time, you need to be very careful, otherwise it will easily constitute a waste.

Because there are too many elements that can make the product appear chattering, we can start with the investigation from these aspects, and we must analyze in detail according to our own factory situation.

Firstly, judge whether there is a “chatter”. The usual rule is: horizontal chatter appears, as shown in the picture, it looks like a spiral pattern with relatively large spacing.

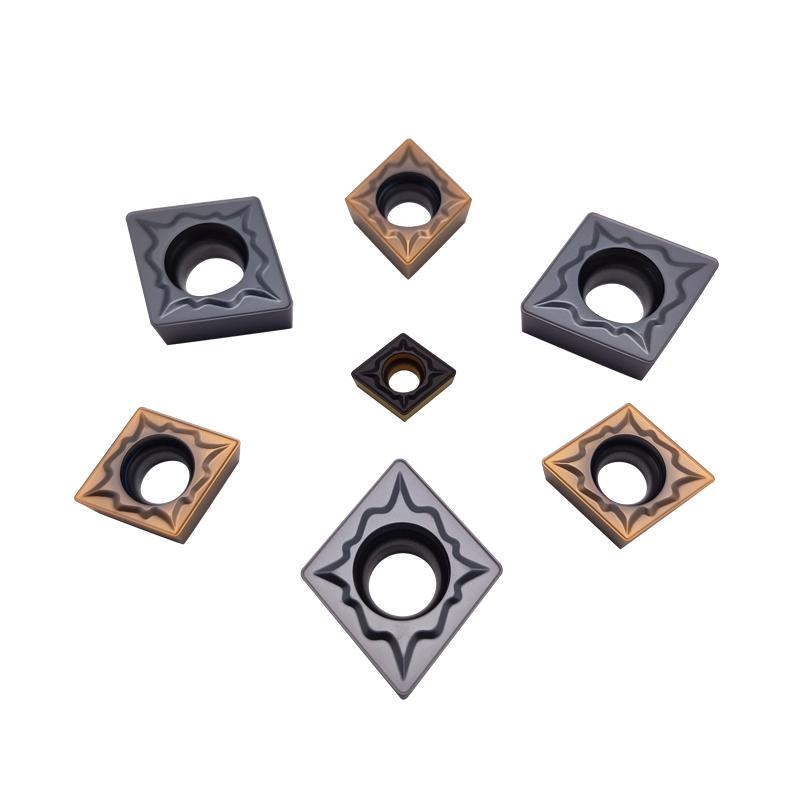

It is necessary to understand whether the workpiece appears chatter marks after one-time machining, or if chatter marks appear after the second finishing.Does the machine collide? If it collides, the Z-axis screw and spindle are likely to have effects, and vibration lines will appear in this case.Check whether the machine speed is within a reasonable range, and at the same time change the rotation feed to the sub-feed in the sequence to try. (The speed of the machine tool is resolutely large, resulting in uneven rotation and feed speed, which will accelerate and decelerate from time to time. If the accuracy of the machine tool private server unit and the actuator is not high enough, it will easily form ripples). What is displayed on the ordinary machine tool panel is the speed reflected by the actual spindle encoder. See whether the speed can be determined at the time of its obligation. The most direct way is to directly change the rotation feed to the component feed. If the effect is improved, then it is ordinary It is the encoder defect or the inverter defect.The rigidity of the drive of the machining center system does not match.The workpiece itself or the fixed rigidity of the workpiece, such as some small and thin parts due to their lack of rigidity, or due to the shape of the workpiece, can not be adequately fixed by the use of a reasonable press fixture.The Z-axis screw supports the bearing, and the loose back cap can easily cause vibration lines.Whether the tool has no effect and whether cutting edge is too large. If the cutting edge of CNC turning insert is too wide, horizontal lines are prone to appear. If you change your hand to sharpen the cutting tools, the vibration can be reduced. Perhaps the tip of the tool sharpens a transitional edge.Rigidity and dynamic balance of external causes relative to the axis of rotation, the mass imbalance caused by external elements will cause chattering due to the unbalanced centripetal force during rotation. Especially in high-speed machining, the dynamic balance of things has a great impact.The selection of cutting parameters includes cutting speed, feed rate and cooling method.The machine tool guide rail of the machining center is loose.In fact, to prevent the occurrence of chatter marks should be avoided from the source, and try to avoid vibration when cutting the workpiece. If you have any questions for CNC cutting tools, just feel free to contact Our for solutions.

Write a Comment