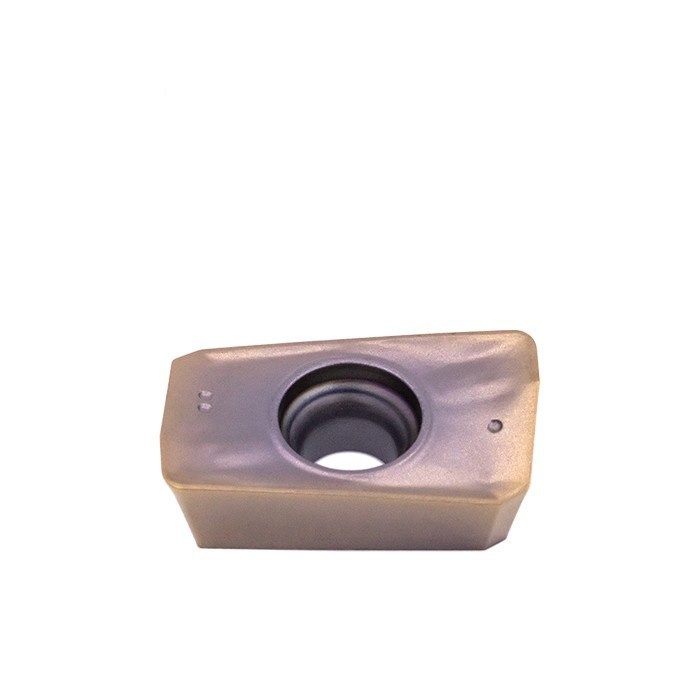

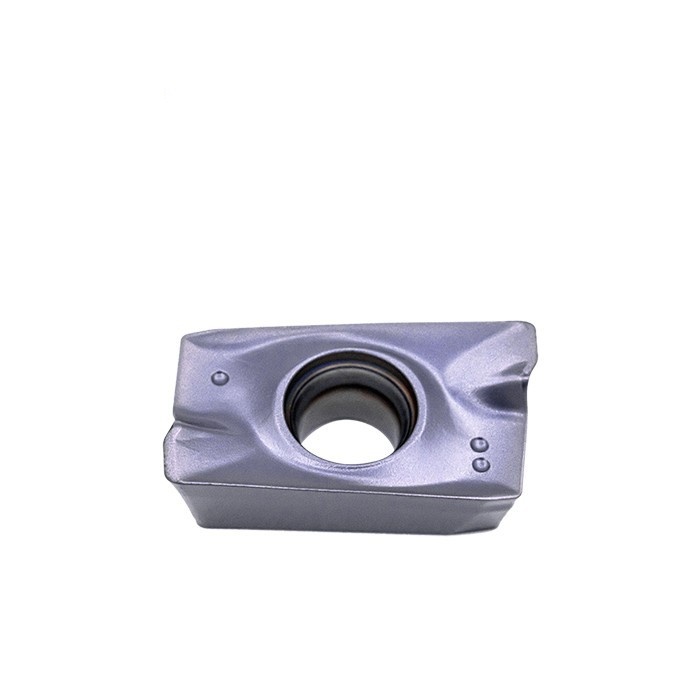

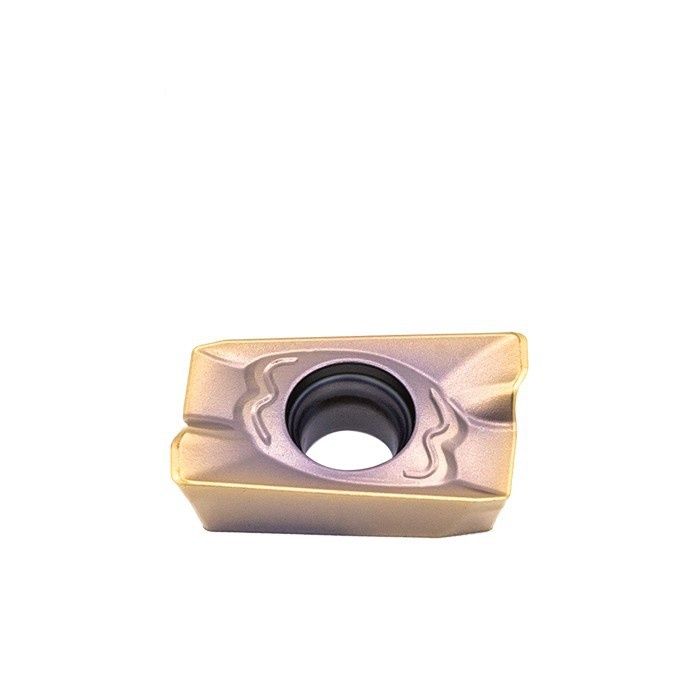

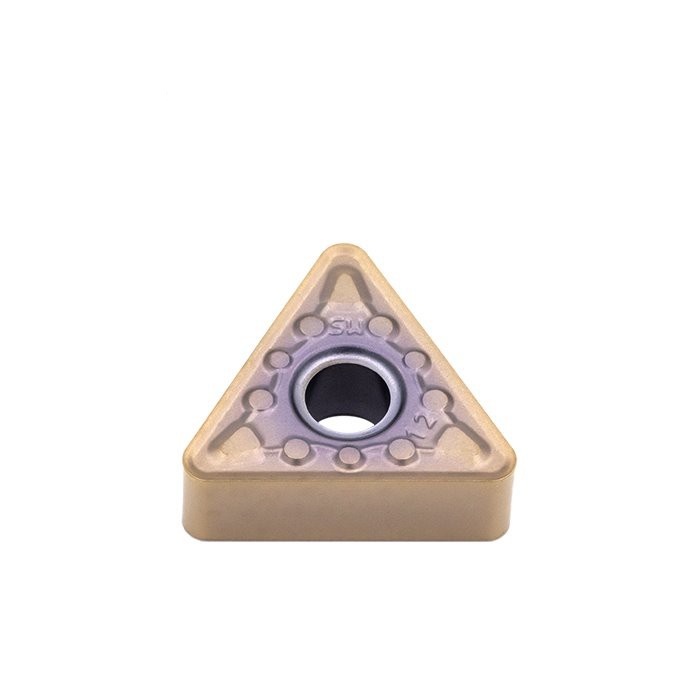

APMT Insert for Reliable Performance in Milling and Slotting Applications Details

Product Information:

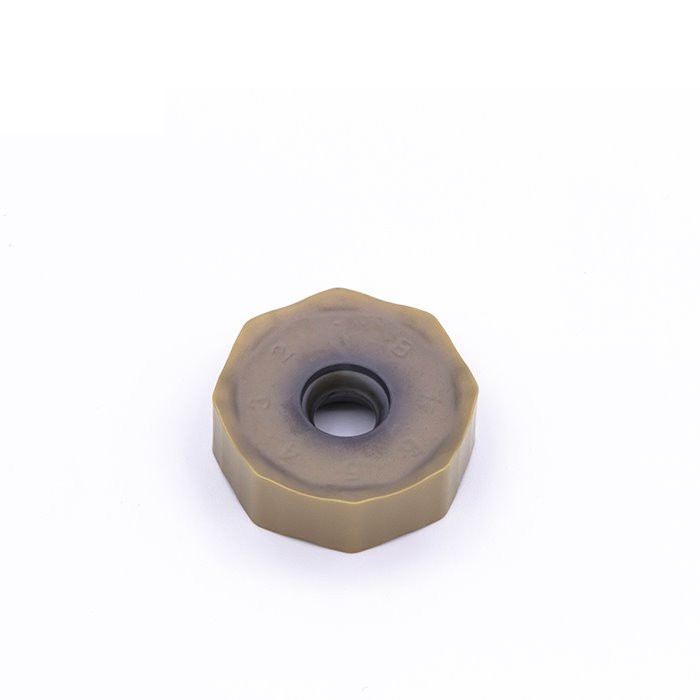

Carbide APMT PVD Coated inserts are commonly used for indexable square shoulder end milling cutters and face milling cutters. The APMT inserts are with precision-molded I.C., positive molded chip breaker. They have a sharp and honed cutting edge and 11° relief angle. They are with screw holes created in compliance with ISO. Typically, it is viewed as with 2 cutting edges. However, they actually have 4 cutting edges. when they are installed on 90° indexable milling cutters and both edges become dull, they can be installed on 75° indexable milling cutters  and continue other milling applications with the other two edges.APMT will be a great choice for end users, since it can significantly improve productivity.

Specifications:

| Type | Ap (mm) | Fn (mm/rev) | CVD | PVD |

VT3020 | VT3040 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1520 | VY1525 | VY1028 | VY1330 |

APMT1135PDER-XR | 2.50-7.50 | 0.05-0.25 |

|

| • | • | O | O |

|

|

|

|

|

APMT1605PDER-XR | 3.50-10.00 | 0.07-0.50 |

|

| • | • | O | O |

|

|

|

|

|

APMT1135PDER-M2 | 2.50-7.50 | 0.05-0.25 |

|

| • | • | O | O |

|

|

|

|

|

APMT160408PDER-M2 | 3.50-10.00 | 0.07-0.30 |

|

| • | • | O | O |

|

|

|

|

|

APMT1135PDER-GM | 2.50- 7.50 | 0.05-0.25 |

|

| • | • | O | O |

|

|

|

|

|

APMT160408PDER-GM | 3.50-10.00 | 0.07-0.50 |

|

| • | • | O | O |

|

|

|

|

|

APMT1135PDER-H2 | 2.50-7.50 | 0.05-0.25 |

|

| • | • | O | O |

|

|

|

|

|

APMT160408PDER-H2 | 3.50-10.00 | 0.07-0.30 |

|

| • | • | O | O |

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

Application:

APMT milling insert with strong geometry design enables to deal with steel.alloy steel, stainless steel, and cast iron.

FAQ:

What are inserts made of?

Almost all the inserts consist of cemented carbide, which results from a combination of tungsten carbide (WC) and cobalt (Co). The hard particles within the insert are WC, while Co can be thought of as the glue that holds the insert together.

What is shoulder milling?

Shoulder milling generates two faces simultaneously, which requires peripheral milling in combination with face milling. Shoulder milling can be performed by traditional square shoulder cutters, and also by using end milling cutters, long-edge cutters and side and face milling cutters.

Our Company

Package Shipment