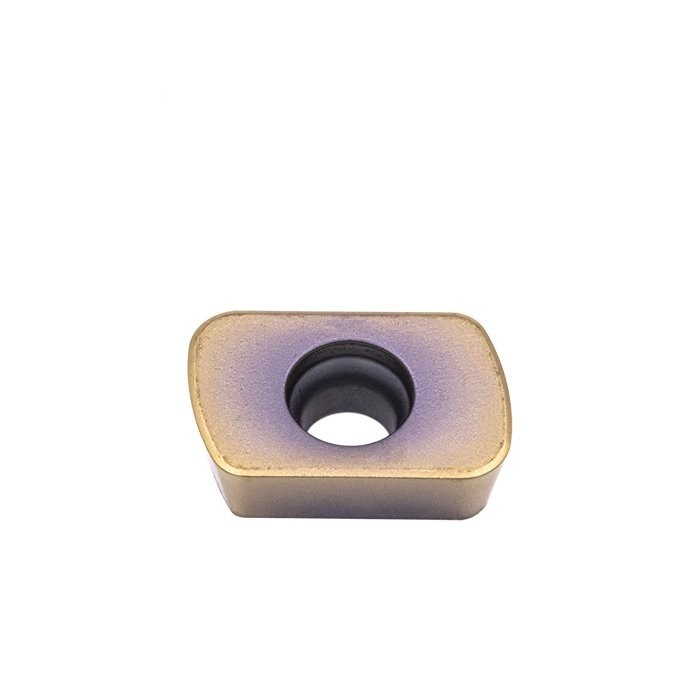

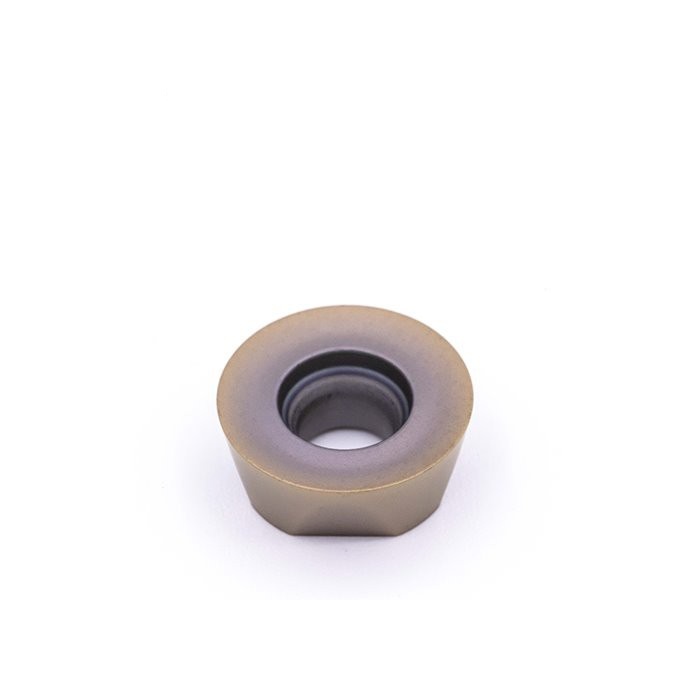

EPNW Milling Insert for Effective Material Removal in Milling Operations Details

Product Information:

High feed cemented carbide milling inserts, good wear and abrasive resistance. Precision ground and polished for high feed milling inserts, better cost-effective CNC tools.

Specifications:

| Type | Ap (mm) | Fn (mm/rev) | CVD | PVD |

VT3020 | VT3040 | VT1015 | VT1025 | VT1824 | VT1825 | VT1525 | VT1828 | VY1010 | VY1520 | VY1525 | VY1029 |

EPNW0603TN-GH | apmax=1.5 | 0.15-0.50 |

|

| O | • | O | • | • | O |

|

|

|

|

• : Recommended Grade

O: Optional Grade

Application:

China manufacturer carbide Milling insert EPNW/EPNW0603TN for high feed milling.

FAQ:

What is high feed milling?

It is a milling method that permits up to three times faster machining than conventional methods. It pairs shallow depth of cut with high feed per tooth which gives higher metal removal rates and results in more parts being machined.

What is CNC face milling?

Face milling is a machining process in which the milling cutting is placed perpendicular to the workpiece. The milling cutting is essentially positioned “face down” towards the top of the workpiece. When engaged, the top of the milling cutting grinds away at the top of the workpiece to remove some of its material.

Our Company

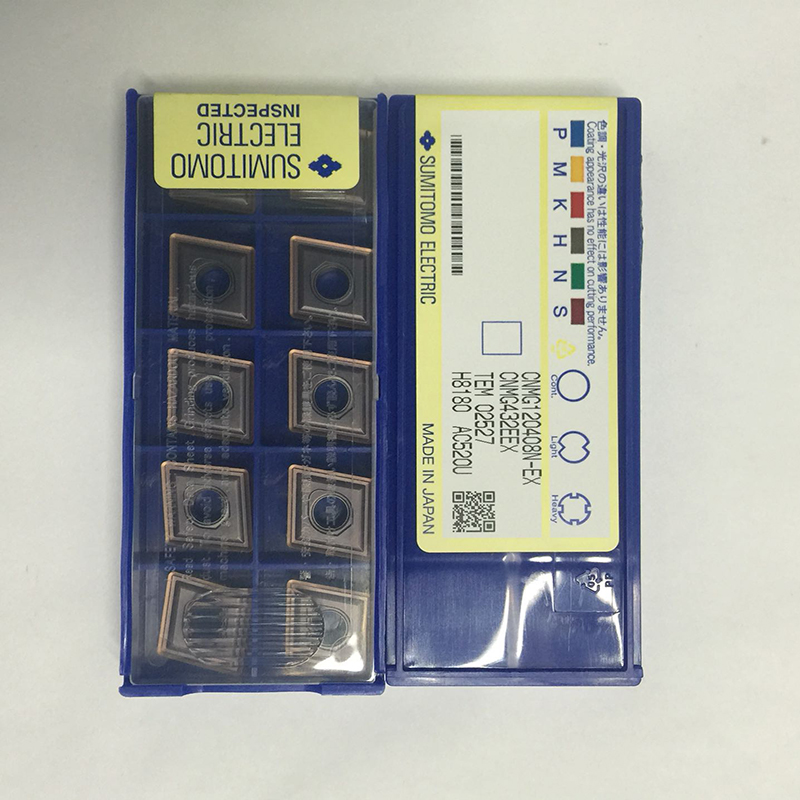

Package Shipment