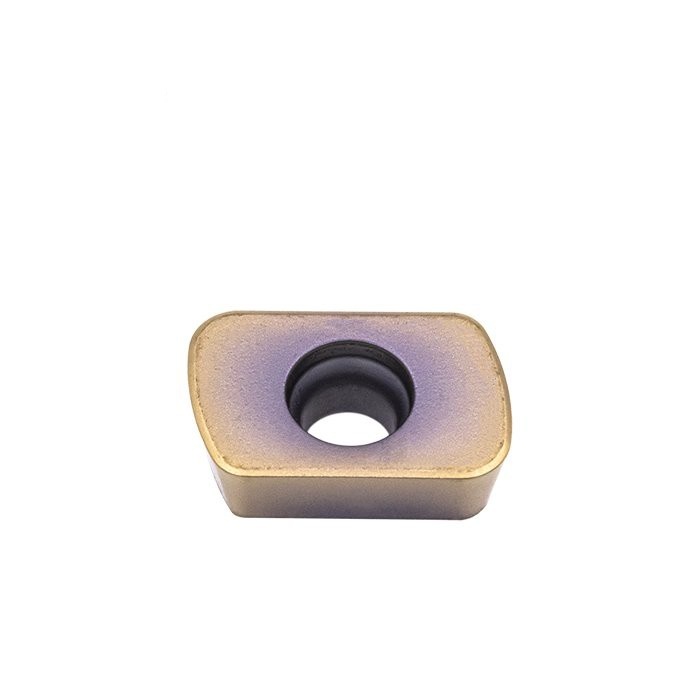

Famous brand Hitachi carbide insert cnc milling tool EPNW0603TN-8 JP4120 Details

Hitachi carbide insert Features:

1.Original famous Japan Hitachi brand;

2.Enables high precision finishing cutting;

3.New coating for carbide milling inserts;

4.Long life provided by new GX coating with excellent wear resistance;

5.Application: Internal & external turning for steel, stainless steel, cast iron and any other hardmetal workpiece;

6.Conditions: Unused, Unopened, Undamaged item in its original packaging.

Hitachi carbide insert Specifications:

| Brand Name | Hitachi |

| Place of Origin | Japan |

| Model Number | Various |

| Material | Tungsten carbide |

| Color | Gold/Black/Gray |

| Certifications | ISO9001:2008 |

| MOQ | 10 PCS |

| Packaging | Original plastic box |

| Delivery time | 1-20 days |

Some Hitachi Carbide Inserts Models for Reference:

ADNT160308SR HC844

ADMT12T308R CY250

ADNT160308SR CH550

APET120204SR CH550

APLT1504ZZR CY250

APMT090208R CY250

APMT1604PDER-HS JP4020

APMT150408R CY250

APNT120208SR CH550

APMT1135PDER-HT JP4020

APMT1604PDER JP4020

CCMT060204 CY250

CPMT160408Z JP4020

CPMT160408Z CY250

CPMT160204 CY250

CPMT120308Z JP4020

CPMT090204Z CY250

EPNW0603TN-8 JX1005

EPNW0603TN-8 JX1045

EDNW15T4TN-15 CY250

JDMT100308R PH30E

JDMT100308R-FW JP4020

JDMT100308R PTH30E

JDMT150520R PTH30E

RDMW0501MOEN ATH08M

RDMW1204MOTN-HS JP4020

RDMX1604MOTN CY250

RDMT0802MOTN CY250/JP4020

RDMT10T3MO JX1005

RPMW1003MOEN SH8020

WDNW120420 JP4020

ZCHG200 PJP08M

ZCEW150CE CY250

SPLT120408 CY25

ZPFW160 PCA15M

ZPFG200 PTH08M

ZCFW160-R1.0-PTH08M

ZPFG120-GH ATH80D

ZCET250CE-N HC844

BCFL-12.5R-150-C25

Main famous brands:

Korloy, Sumitomo, Kyocera, Iscar, SECO, Dijet, Kennametal, Tungaloy, Mitsubishi, Hitachi, Valenite, Walter, Taegutec, ZCCCT, OSG,LINKS,STWC,Lamina,etc.

Packing& Shipping:

Packaing:10 pcs/plastic box, then by carton;

Shipping method:by air or by sea. We have a long-term cooperation with DHL, Fedex and UPS logistics company, and often get special discount about the freight charge;

Delivery time: Short, some models are in stock;

Our service:

Best Price: Our prices are more competitive than other suppliers'. And the more you order, the more discount you will get.

Short Delivery: We will arrange the order for you after the payments. The rich stock will guarantee the timely delivery time.

High Quality: The high cutting efficiency will enoughly satisfy your requirement.

Our Company

Package Shipment