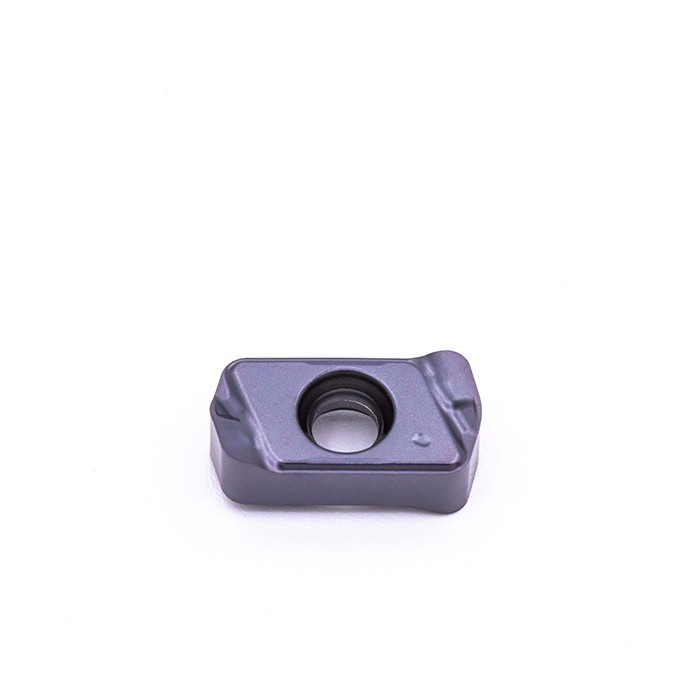

LNMU Insert: Unlock Precision Machining Solutions for Complex Components Details

Product Information:

High feed milling tools save time by avoiding semi finishing and reducing tool

changes. Our expansive range of high feed milling solutions meets all application

needs.LNMU insert is one kind of high feed milling insert. Double-sided fast feed, 4 edges is very cost-effective. Good wear and abrasive resistance. Precision ground and polished milling inserts.

Specifications:

class="table" >

Type | Ap (mm) | Fn (mm/rev) | CVD | PVD |

VT3020 | VT3040 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1520 | VY1525 | VY1028 | VY1330 |

LNMU0303ZER-GM | 0.20-2.00 | 0.50-1.30 |

|

| • | • | O | O |

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

Application

The type of carbide grade and the coating on inserts are originally intended for milling stainless steel, but it also works when milling other alloys.

FAQ:

Where is tungsten carbide manufactured?

There are many company manufacture tungsten carbide.but approximately 85% of the world's tungsten comes from China .Zhuhzou city is the largest tungsten carbide products manufacturing center in Asia.

What is high speed machining?

High-feed milling is a machining method that pairs shallow depth of cut with high feed rate. It can achieve a very high metal-removal rate, high-speed machining to reduce cycle time, increase tool life and productivity.

Our Company

Package Shipment