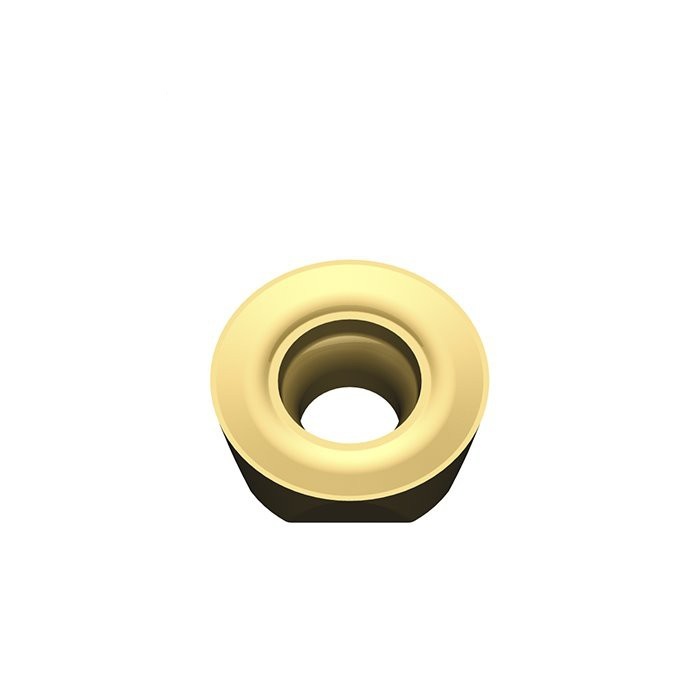

PNCU Insert for Precise and Stable Machining in Fine Finishing Details

Product Information:

PNCU Inserts. Double sided pentagonal insert.Pressed rake face geometry promotes efficient chip formation. Integrated wiper flat produces surface finishes. Designed for multiple materials and facing applications 10 indexes.

Specifications:

Type | Ap (mm) | Fn (mm/rev) | VT3020 | VT3040 | VT1025 | VT1325 | VT1525 | VT1328 | VY1020 | VY1520 | VY1525 | VY1028 | VY1330 |

PNCU0905GNEN-GM | 0.50-3.00 | 0.20-0.60 |

|

| • | • | O | O |

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

Application:

Designed for utmost surface finishes on Steel, Iron, high-Temperature Alloys, stainless steel.

FAQ:

What are face mills?

Face milling is a machining process in which the milling cutting is placed perpendicular to the work piece. The milling cutting is essentially positioned “face down” towards the top of the work pieces. When engaged, the top of the milling cutting grinds away at the top of the work piece to remove some of its material.

What is the difference between face milling and end milling?

These are two of the most prevalent milling operations, each using different types of cutters – the and mill and the face mill. The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting.

Our Company

Package Shipment