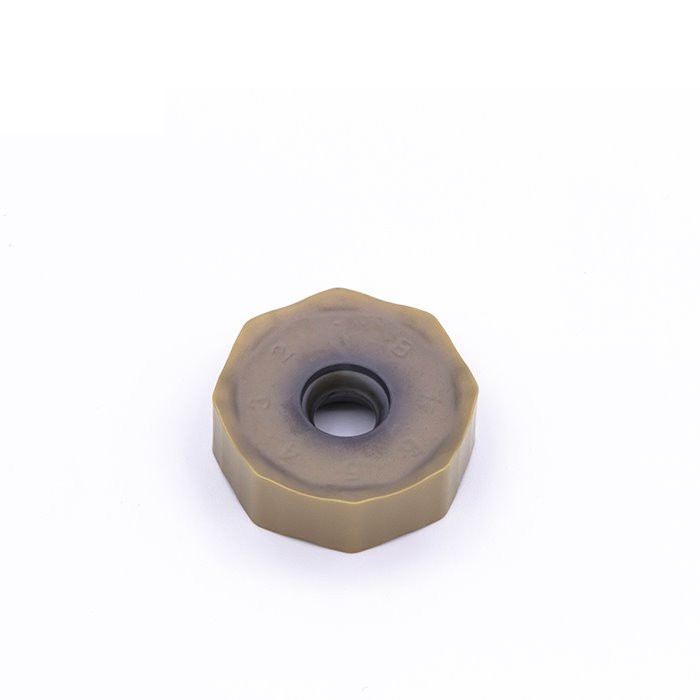

SPMT Insert: Precision and Speed Combined for Efficient Machining Details

Product Information:

Helical milling is a hole-making machining process in which the cutter proceeds a helical path while rotating around its own axis, used to produce helical parts like helical gears, spiral flute milling cutters, twist drills, and helical cam grooves.

SPMT for helical milling.

S - Square shape of turning insert.

P - Insert with clearance under main cutting edge (11°).

M - Tolerances and dimensions of carbide turning insert.

T - Hole through insert and single sided chip breaker.

Specifications:

class="table" >

|

Type

|

Ap

(mm)

|

Fn

(mm/rev)

|

CVD

|

PVD

|

|

VT3020

|

VT3040

|

VT1025

|

VT1325

|

VT1525

|

VT1328

|

VY1010

|

VY1520

|

VY1525

|

VY1028

|

VY1330

|

|

SPMT120408-PM

|

1.00-6.00

|

0.06-0.15

|

|

|

•

|

•

|

O

|

O

|

|

|

|

|

|

|

SPMT120408-KM

|

1.00-6.00

|

0.06-0.15

|

|

|

•

|

•

|

O

|

O

|

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

Application

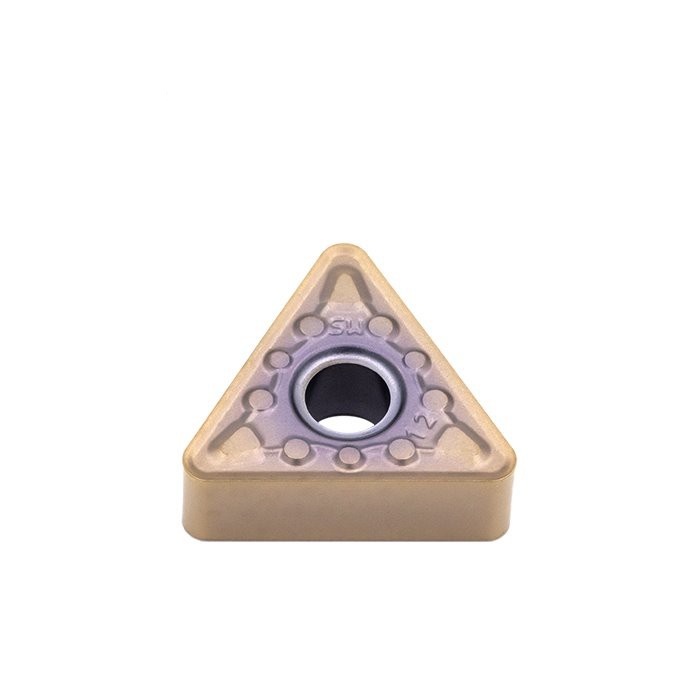

The type of carbide grade and the coating on inserts are originally intended for steel, stainless steel and cast iron. But it also performs when milling other alloys.

FAQ:

What is helical milling?

Helical milling is a hole-making process in which the milling tool proceeds a helical path while rotates around its own axis, presenting several advantages in relation to conventional drilling. The helical path can be decomposed into axial and tangential directions, combining frontal and peripheral cutting.

How do I choose the milling insert?

Selecting the milling insert based on the application of demands and the space for the cutting tools. the larger of the insert.the better of the stability . For heavy machining, the insert size is normally above 1 inch. finishing, the size cans be reduced.

Our Company

Package Shipment