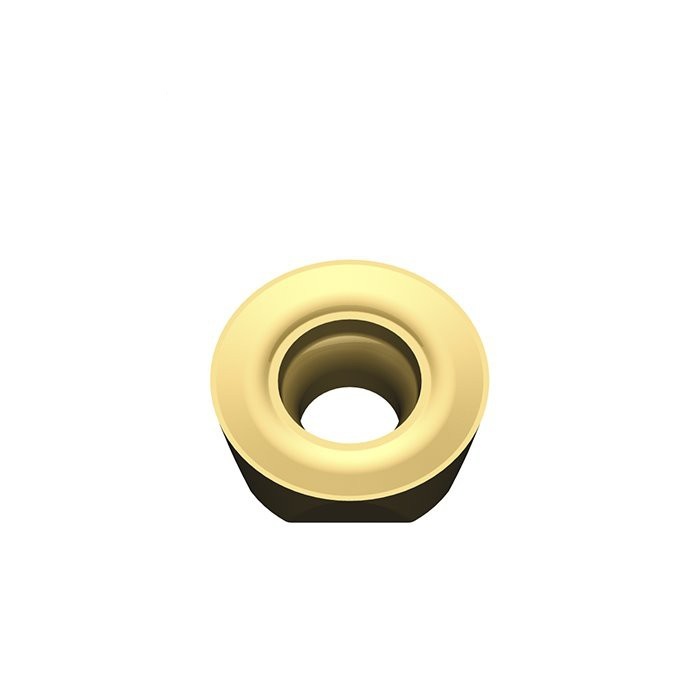

TNGG Insert for Efficient Grooving and Threading Operations Details

Product Information:

TNGG insert with negative relief angle, G class, triangular insert, for precision finishing. 6 cutting edges . With 0 degrees clearance angle major (AN).TNGG three sides of equal length that form three cutting points with 60° nose angles. These indexable inserts mount to a compatible toolholder, which attaches to a lathe or CNC turning machine. They can be rotated (indexed) to expose a fresh cutting edge when the old one dulls. They can be replaced with new compatible inserts of the same style or a different style without removing the toolholder from the machine.Indexable turning tools require fewer tool changes than solid tools in high-volume metalworking and fabrication applications with high speeds, high feeds, and difficult-to-machine materials.

Specifications:

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT4235 | VT4335 | VT1005 | VT1035 | VT1328 | VT1505 | VY1525 | VY1010 |

| Small Parts Machining | TNGG160401-FS | 0.4-1.5 | 0.02-0.06 |

|

|

|

|

|

| • | O |

| O |

|

|

TNGG160402-FS | 0.6-2.0 | 0.04-0.08 |

|

|

|

|

|

| • | O |

| O |

|

|

TNGG160404-FS | 0.8-2.5 | 0.06-0.10 |

|

|

|

|

|

| • | O |

| O |

|

|

• : Recommended Grade

O: Optional Grade

Application:

Application for making longitudinal cuts, turning, facing, and chamfering in light roughing and finishing applications.

FAQ:

What are the types of insert?

Cutting tool inserts.

Cutting insert.

Isostatic mounting.

Thread cutter.

Carbide cutting tool and insert.

Flat bottom drill.

HSS drill inserts.

Positive square inserts.

What is the difference between face milling and end milling?

These are two of the most prevalent milling operations, each using different types of cutters – the and mill and the face mill. The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting.

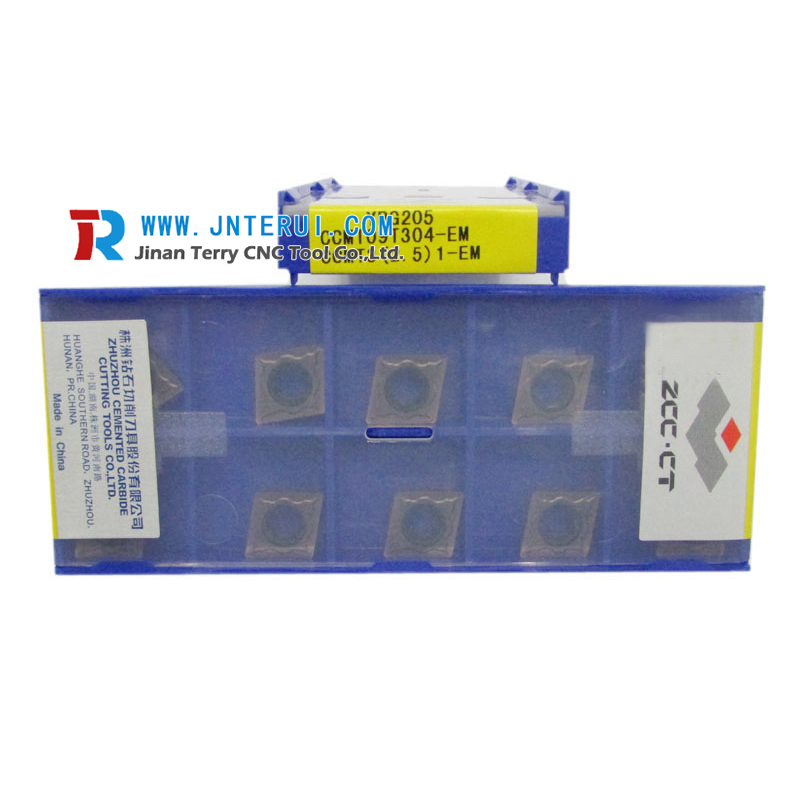

Our Company

Package Shipment