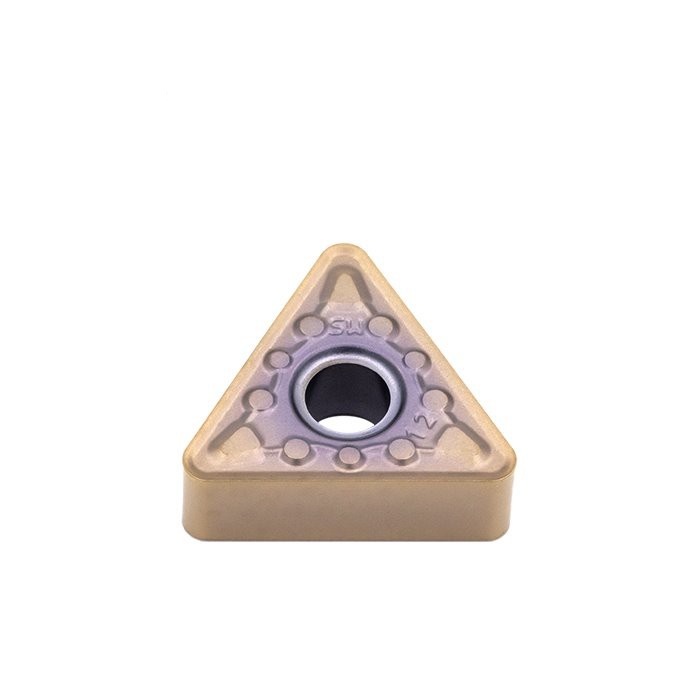

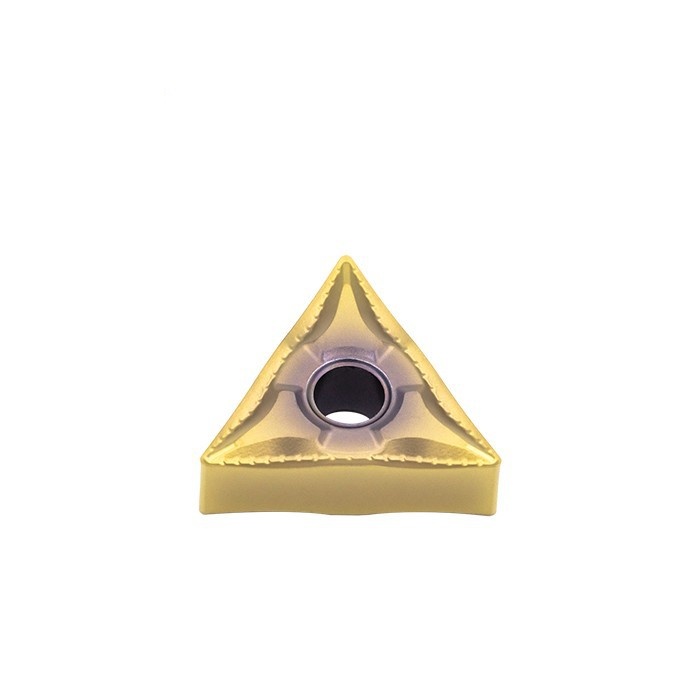

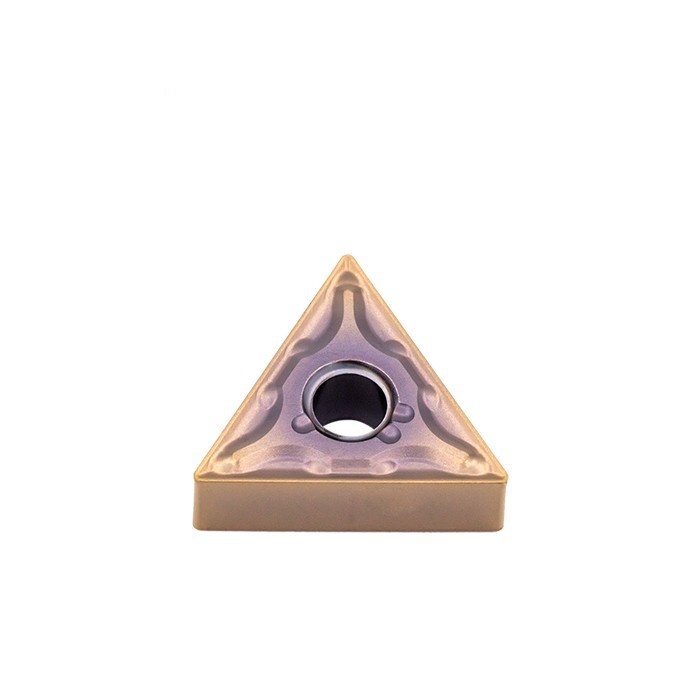

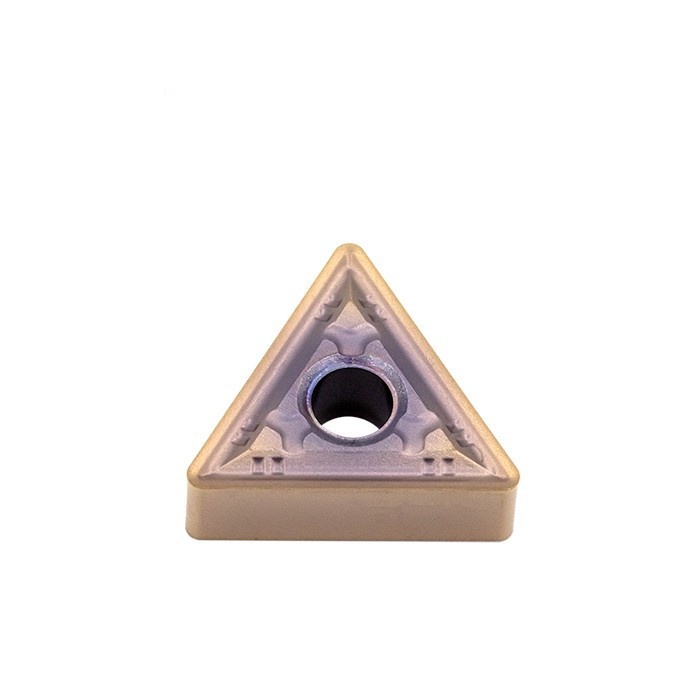

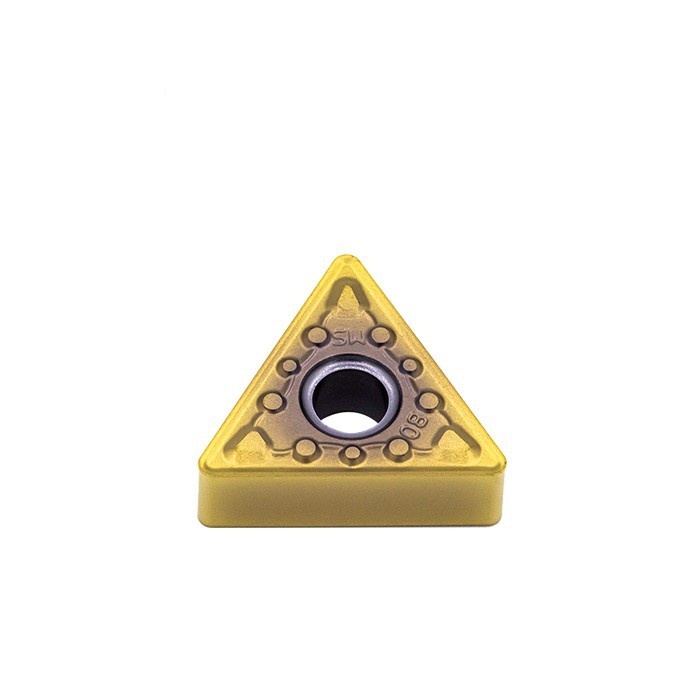

TNMG Insert for Versatile Turning and Boring Operations Details

Product Information:

TNMG Insert is the triangle shape with negative angles to guarantee efficient machining and high stability. For a wide range of materials and machining conditions.Double-sided, for semi-roughing and roughing.

Specifications:

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT4235 | VT4335 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1325 |

P Semi Finishing | TNMG160404-AM | 0.60-5.80 | 0.10-0.30 | • | O | • |

| O | O |

|

|

|

|

|

|

TNMG160408-AM | 1.20-5.80 | 0.20-0.60 | • | O | • |

| O | O |

|

|

|

|

|

|

TNMG160412-AM | 1.80-5.80 | 0.30-0.90 | • | O | • |

| O | O |

|

|

|

|

|

|

TNMG220408-AM | 1.20-7.70 | 0.20-0.60 | • | O | • |

| O | O |

|

|

|

|

|

|

TNMG220412-AM | 1.80-7.70 | 0.30-0.90 | • | O | • |

| O | O |

|

|

|

|

|

|

TNMG220416-AM | 2.40-7.70 | 0.40-1.20 | • | O | • |

| O | O |

|

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT4235 | VT4335 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1325 |

P Rough Machining | TNMG160408-AR | 2.00-5.00 | 0.25-0.65 |

|

| • | O |

|

|

|

|

|

|

|

|

TNMG220408-AR | 2.50-7.00 | 0.25-0.65 |

|

| • | O |

|

|

|

|

|

|

|

|

TNMG220412-AR | 2.50-7.00 | 0.25-0.65 |

|

| • | O |

|

|

|

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1325 | VY1525 | VY1330 |

M Finishing | TNMG160404-BF | 0.25-3.10 | 0.05-0.15 |

|

|

|

|

| • | • |

| O |

| O |

|

TNMG160408-BF | 0.50-3.10 | 0.10-0.30 |

|

|

|

|

| • | • |

| O |

| O |

|

TNMG160412-BF | 0.75-3.10 | 0.10-0.30 |

|

|

|

|

| • | • |

| O |

| O |

|

• : Recommended Grade

O: Optional Grade

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1325 | VY1525 | VY1330 |

M Semi Finishing | TNMG160404-BM | 0.30-4.10 | 0.08-0.25 |

|

|

|

|

| O | O | • | O |

| O |

|

TNMG160408-BM | 0.65-4.10 | 0.15-0.45 |

|

|

|

|

| O | O | • | O |

| O |

|

TNMG160412-BM | 0.95-4.10 | 0.25-0.65 |

|

|

|

|

| O | O | • | O |

| O |

|

TNMG220408-BM | 0.65-4.90 | 0.15-0.45 |

|

|

|

|

| O | O | • | O |

| O |

|

TNMG220412-BM | 0.95-4.90 | 0.25-0.65 |

|

|

|

|

| O | O | • | O |

| O |

|

• : Recommended Grade

O: Optional Grade

| Application | Type | Ap (mm) | Fn (mm/rev) | CVD |

VT3020 | VT3040 | VT3315 | VT3415 |

K Semi Finishing | TNMG160404-CM | 0.40-4.10 | 0.08-0.25 |

|

| • | O |

TNMG160408-CM | 0.80-4.10 | 0.15-0.45 |

|

| • | O |

TNMG160412-CM | 1.20-4.10 | 0.25-0.65 |

|

| • | O |

TNMG220412-CM | 1.20-4.90 | 0.25-0.65 |

|

| • | O |

• : Recommended Grade

O: Optional Grade

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1325 | VY1525 | VY1330 |

M Rough Machining | TNMG160404-BR | 0.30-4.10 | 0.08-0.25 |

|

|

|

|

| O | O | • | O |

| O |

|

TNMG160408-BR | 0.65-4.10 | 0.15-0.45 |

|

|

|

|

| O | O | • | O |

| O |

|

TNMG160412-BR | 0.95-4.10 | 0.25-0.65 |

|

|

|

|

| O | O | • | O |

| O |

|

TNMG220408-BR | 0.65-4.90 | 0.15-0.45 |

|

|

|

|

| O | O | • | O |

| O |

|

TNMG220412-BR | 0.95-4.90 | 0.25-0.65 |

|

|

|

|

| O | O | • | O |

| O |

|

• : Recommended Grade

O: Optional Grade

Application:

The TNMG Insert is mainly used in the fields of metal turning, milling, cutting and grooving, thread turning, etc. Application for steel material.

FAQ:

What is TNMG insert?

TNMG inserts are ISO turning inserts and most commonly used in almost all CNC Lathes. It is used for Profile Turning applications and general shaft turning applications. Insert is having 6 cutting edges.

What is the difference between face milling and end milling?

These are two of the most prevalent milling operations, each using different types of cutters – the and mill and the face mill. The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting.

Our Company

Package Shipment