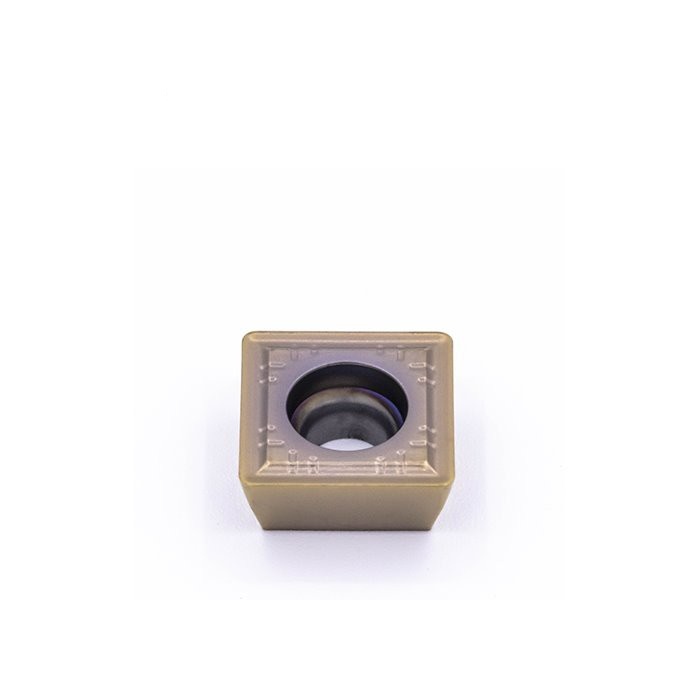

Tungaloy carbide inserts cnc milling inserts LNMU0303ZER-MJ AH725 Details

Tungaloy cutting tools grade description:

P Steel (coating CVD)

T9005 steel processing materials;

T9015 Bridging effect can be achieved by good coverage spalling resistance; using a dedicated group

T9025 series and four kinds of materials can be applied to all areas of the steel turning.

T9035 / T9005: high-speed cutting and other requirements in the field of anti-wear properties, can play a good performance.

T9015: resistance to cutting conditions abrasion resistance and chipping resistance balance of a wide range of cooperation,

T9025: ~ moderate in light intermittent cutting, play good resistance to chipping,

T9035: has a very high chipping resistance, more suitable for strong interrupted cutting.

M stainless steel

T6020 stainless steel processing used materials. M stainless steel

T6030 uses a combination of dedicated high-density substrate and coating, significantly improved resistance to extreme wear resistance and chipping resistance.

T6020: Applicable speed ~ high speed areas, serials ~ light interrupted cutting.

T6030: Applicable areas of low to medium speed, very high chipping resistance, continuous – interrupted cutting.

K cast iron

T5104: cast iron, ductile iron,

T5115: coating using a higher hardness than ever finer columnar crystals Ti film, greatly improve the wear resistance. And by high-strength.

T5010: a combination of dedicated particle cemented carbide substrate, so

T5100 series three kinds of material

T5020: quality in wide range of areas FC.FCD Turning to achieve superior performance.

T5105: play good wear resistance and resistance to plastic deformation at high speed, continuous cutting.

T5115: from the continuous cutting to even intermittent, intermittent cutting of wide range of areas, you can achieve a stable common processing material.

T5125: for strong interrupted cutting, more tough, difficult to appear sudden chipping.

P steel (uncoated)

NS730: steel with anti-chipping materials. Heat chipping, chipping excellent mechanical properties. Excellent value for money.

NS740: milling with high toughness materials. Better wear resistance and thermal cracking of high-reliability material.

NS520: steel, cast iron, high-speed, efficient processing materials. Since the crude and the introduction of new sintering method, it is an excellent wear resistance and toughness of the hard particles collapse.

NS530: steel, cast iron with a universal material. The wear resistance and toughness of both materials.

NS540: the milling material. Thermal cracking performance, wear resistance and toughness of both materials.

NS520: steel, cast iron, high-speed, efficient processing materials. Since the crude and the introduction of new sintering method, it is an excellent wear resistance and toughness of the hard particles collapse.

NS530: steel, cast iron with a universal material. The wear resistance and toughness of both materials.

Features of Tungaloy cnc milling inserts

1).Japan Tungaloy brand;

2).Tungaloy carbide inserts are for general purpose / multi-purpose cutting;

3).Improved chipping resistance;

4).Stronger coating adhesion;

5).Improved wear resistance;

6).Stability and security in productive turning;

7).Long tool life in continous and interrupted cutting;

8).Various types and grades for choices.

Main Parameter of Tungaloy cnc milling inserts

1).Famous Brand: Tungaloy;

2).Place of Origin: Japan;

3).Material: Tungsten Carbide/Hard Alloy/Cermet;

4).Delivery: Short;

5).MOQ: 10 pieces (1 box);

6).Package: Original plastic box.

FAQ:

How long have you done in this industry?

Over 8 years specializing in producing non-standard cutting tools

How do I pay for my purchase?

Credit card, Western union, Paypal, T/T, L/C

Do you accept trial order?

Sure we can. And we would like to quote our most favorable price if your order is big enough.

Are your products are original?

All our products are directly from Country of Origin, so our products are all original.

Our Company

Package Shipment