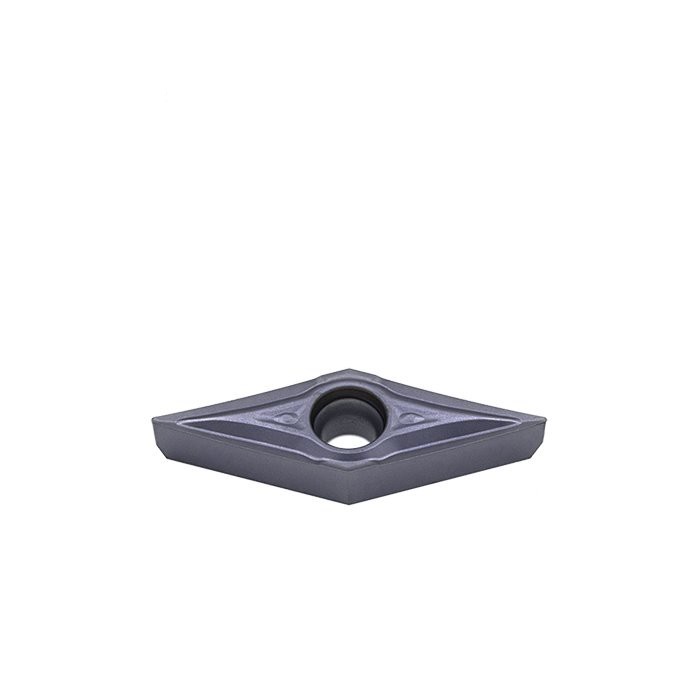

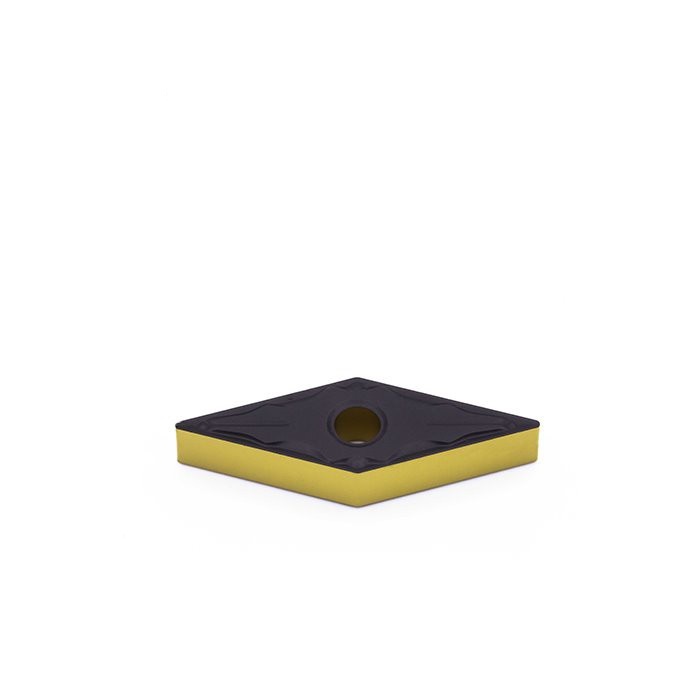

VBGT Insert for Reliable Performance in Turning and Boring Applications Details

Product Information:

VBGT insert included angle 35 degree. Clearance angle of indexable insert ISO: B (5°)

Tolerance class of indexable insert ISO: G. Very high level of hardness and wear resistance, for high service life requirements with favourable cutting conditions.High positive rake on the nose and CE, less cutting forces.Positive soft-cutting chip geometry with a wide infeed range and stable blades.

Specifications:

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT4235 | VT4335 | VT1005 | VT1035 | VT1328 | VT1505 | VY1525 | VY1010 |

| Small Parts Machining | VBGT110301-FS | 0.1-1.5 | 0.02-0.06 |

|

|

|

|

|

| • | O |

| O |

|

|

VBGT110302-FS | 0.2-2.0 | 0.05-0.12 |

|

|

|

|

|

| • | O |

| O |

|

|

VBGT110304-FS | 0.2-2.5 | 0.08-0.25 |

|

|

|

|

|

| • | O |

| O |

|

|

• : Recommended Grade

O: Optional Grade

Application:

For longitudinal turning and copy turning with a wide infeed range in favourable cutting conditions.

FAQ:

What are face mills?

Face milling is a machining process in which the milling cutting is placed perpendicular to the workpiece. The milling cutting is essentially positioned “face down” towards the top of the workpiece. When engaged, the top of the milling cutting grinds away at the top of the workpiece to remove some of its material.

What is the difference between face milling and end milling?

These are two of the most prevalent milling operations, each using different types of cutters – the and mill and the face mill. The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting.

Our Company

Package Shipment