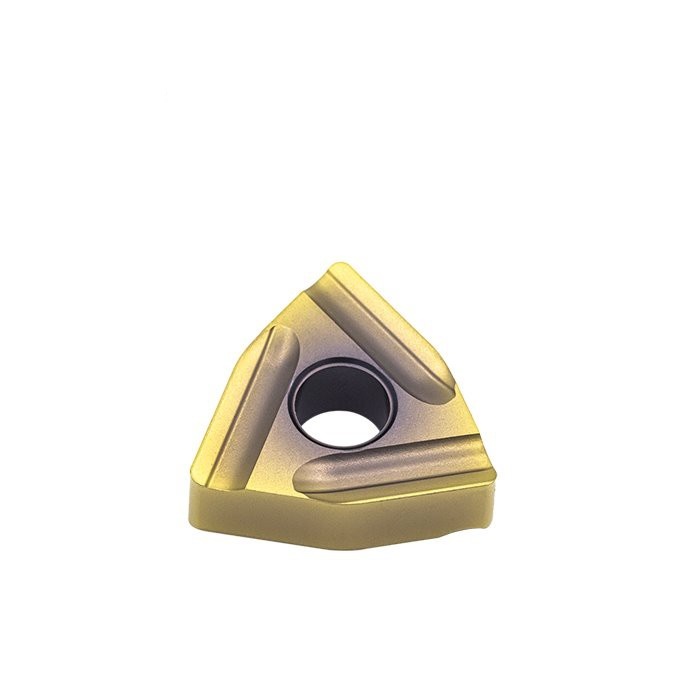

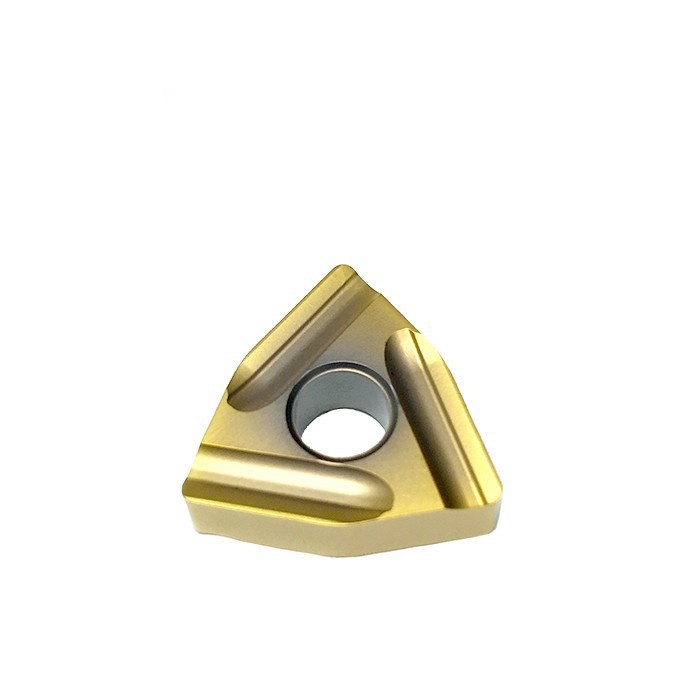

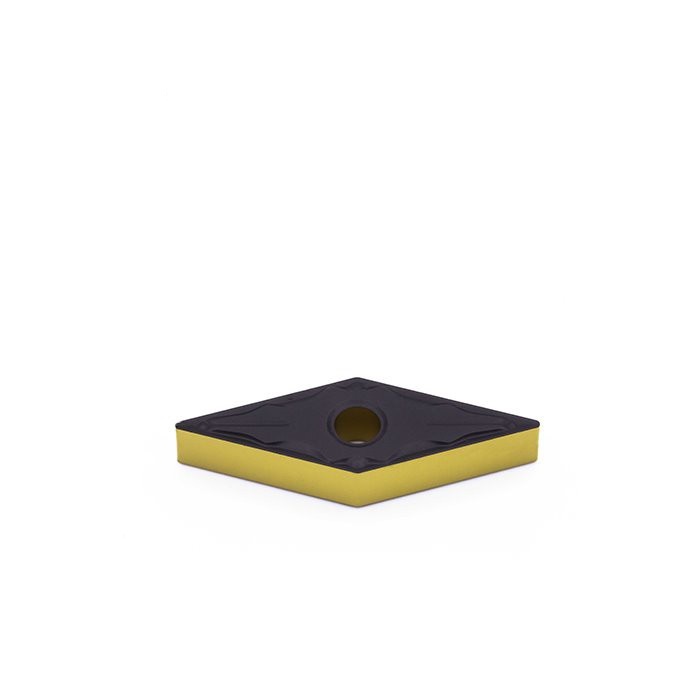

WNMG Insert for Efficient Turning and Boring Operations Details

Product Information:

For the processing of steel. Better smoothness.

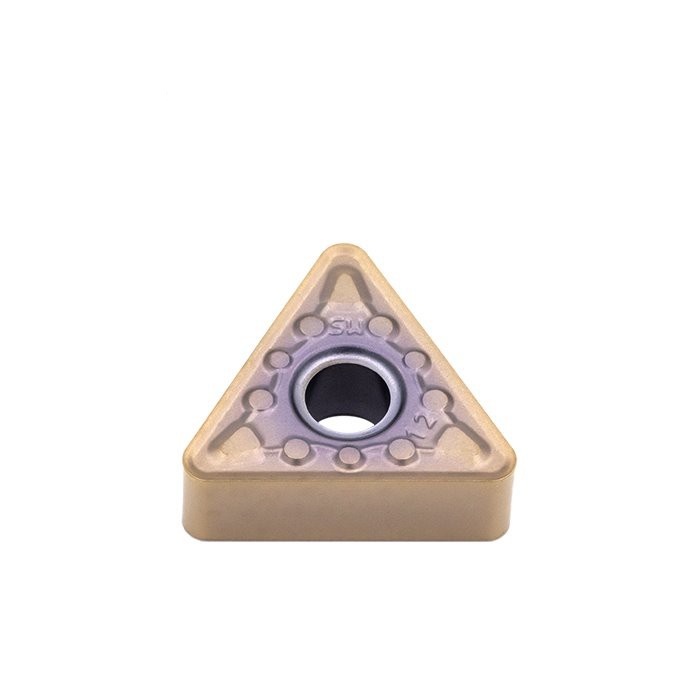

Products made in China. Full fine grinding of the surface of the surrounding surface with a sharp edge. The cutting is more relaxed. Higher durability.

Specifications:

Type | CVD | PVD |

VT4225 | VT4225 | VT4025 | VT1225 | VT1825 | VT1525 | VT1328 |

WNMG080408L-S | O | • | • |

|

|

|

WNMG080408R-S | O | • | • | • |

|

|

• : Recommended Grade

O: Optional Grade

Application:

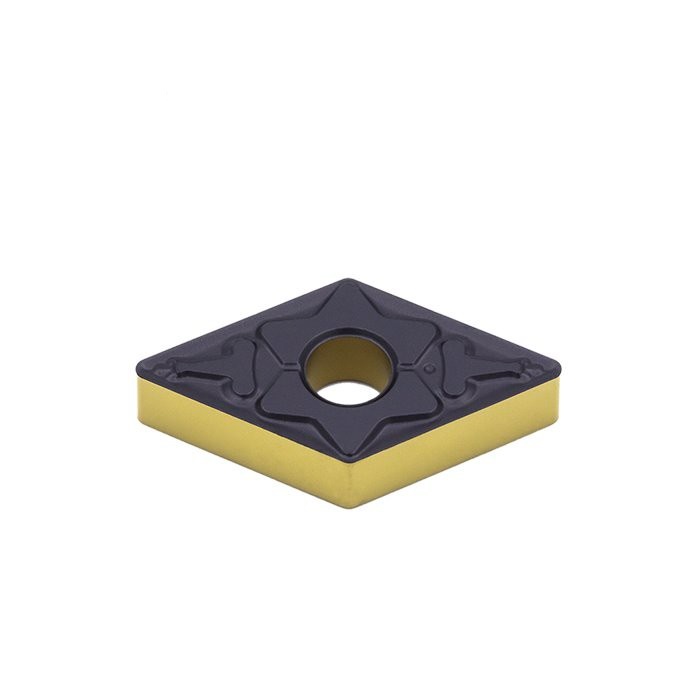

Made of solid carbide with mutilayer coated, offer long life and faster cutting speed, low friction coefficient, good wear resistance. For rough turning steels, tools steel and stainless steel.

FAQ:

What is roughing machining?

The roughing operation in machining is primarily used to remove the bulk material and to approximately shape the workpiece towards the fin- ished form. The manufacturing process described, utilizes a three-axis CNC machine with an indexable fourth axis device that is used to hold and rotate the workpiece.

What is the difference between rough turning and finish turning?

Rough turning operation aims to machine a piece to within a predefined thickness, by removing the maximum amount of material in the shortest possible time, disregarding the accuracy and surface finish. Finish turning produces a smooth surface finish and the workpiece with final accurate dimensions.

Our Company

Package Shipment