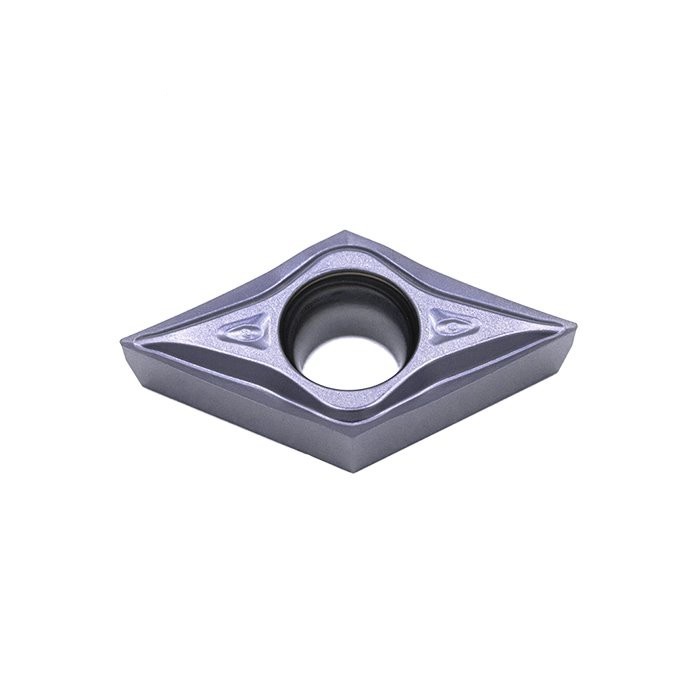

XNEX CNC Insert for Precise and Smooth Machining Results Details

Product Information:

XNEX are double-sided 6-corner tungsten carbide milling inserts for Facing, shouldering, Slotting, helical and ramping. Designed to provide high speed and feed. Wide minor cutting edge improve surface finish. High rake cutting edge improve machinability and reduce cutting resistance.

Specifications:

Type | Ap (mm) | Fn (mm/rev) | CVD | PVD |

VT3020 | VT3040 | VT1015 | VT1025 | VT1824 | VT1825 | VT1525 | VT1828 | VY1010 | VY1520 | VY1525 | VY1029 |

XNEX080608TR-GL | 0.80-8.00 | 0.10-0.30 |

|

| O | • | O | • | • | O |

|

|

|

|

XNEX080612TR-GL | 0.80-8.00 | 0.10-0.30 |

|

| O | • | O | • | • | O |

|

|

|

|

XNEX080608TR-GM | 0.80-8.00 | 0.10-0.30 |

|

| O | • | O | • | • | O |

|

|

|

|

• : Recommended Grade

O: Optional Grade

Application:

Milling Insert, XNEX Insert, 080608 Insert, Trigon Shape, 12.5 mm Inscribed Circle, 6.5 mm Thickness, 0.491 in Width, M13 M09 Chipbreaker, 0.8 mm Corner Radius, ANSI Code: XNEX080608TR-M13, ISO Code: XNEX080608TR-ME09, Right Hand, Carbide, CVD-TiCN/Al2O3

FAQ:

What is insert cutting tool?

Cutting tool inserts are replaceable attachments for cutting tools that typically contain the actual cutting edge. Cutting tool inserts applications include: boring. construction.

What is insert grade?

An insert's material, or grade, is designed to suit a particular machining application, and even though two inserts may look the same, the base material and the coating (if there's one) can be very different

Our Company

Package Shipment